PA Items

Overview

A PA item contains the following information:

- Affected Product/Process: Which product, lot, batch number? Which process?

- Issue description: What could go wrong?

- Detection date

- Assignee: who is responsible for this preventive action?

- Root Cause: why could the issue possibly happen?

- Preventive Action(s): Based on the root cause, which actions need to be taken to avoid it from happening?

Note that these fields can be adjusted in the admin client.

Risk Analysis

Risk analysis should be performed in the appropriate Matrix Requirements project.

When the preventive action is related to a process, the risk analysis should be done in the QMS project.

When the preventive action concerns a product, the risk analyis should be done in the appropriate product project.

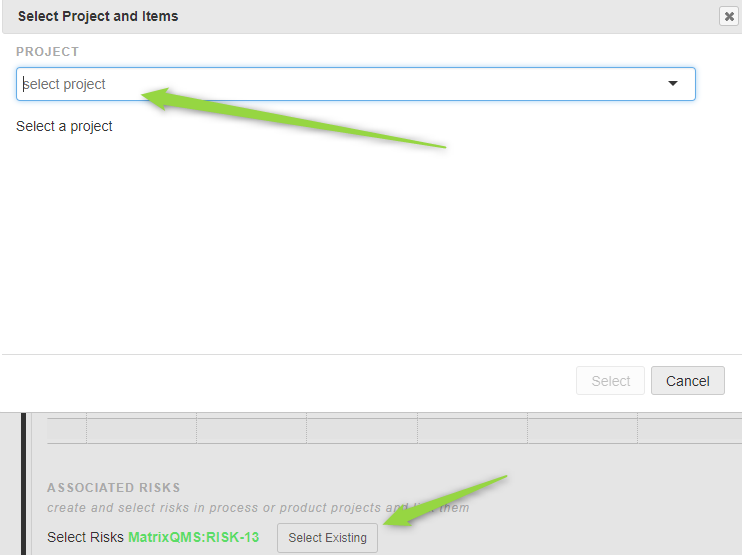

This can be selected when clicking on Select Existing.

After selecting the right project, you can select one or more appropriate risks for this preventive action.

Workflow

On the top of a PA item, there are 2 labels.

The first one can be set to:

- Open: the actions are not yet fully implemented

- Waiting for Effectivenes Check: the actions are fully implemented and the effectiveness check can be performed

- Effectiveness Checked: the effectiveness check has been performed and passed

The second one indicates whether the preventive action is fully done or not. It is a confirmation of whether all defined actions have been implemented and passed their effectiveness check.

When this is the case, the PA item can be closed by entering a signature and if needed, additional comments.